In the metals service industry, PVF stands for pipe, valves, and fittings. When put together, pipes, valves, and fittings are the components that allow substances to flow from one place to another.

From the water we drink to the gas we use to fill up our cars, PVF plays an essential role in our everyday life. Depending on the application, pipes, valves, and fittings come in a variety of different shapes and sizes and are made from a number of different metals and non-metals.

So what is PVF? And why is it important?

What is PVF?

Although pipes, valves, and fittings are all often put into the same category together (hence the unifying acronym), they all have their own individual characteristics and purposes.

Pipes: are hollow, tubular structures made out of a wide variety of metal and non-metal materials that are used to carry or transfer substances such as liquids, gases, or masses of small solids. Though sometimes thought of as tubes, piping and tubing have significant differences that are critical to understand when working with them. Learn about the differences between pipes and tubes here!

Valves: are mechanical devices used to regulate, control, or direct the flow and pressure of substances within a piping system. Valves work by opening, closing, or partially obstructing the flow of substances running through pipes.

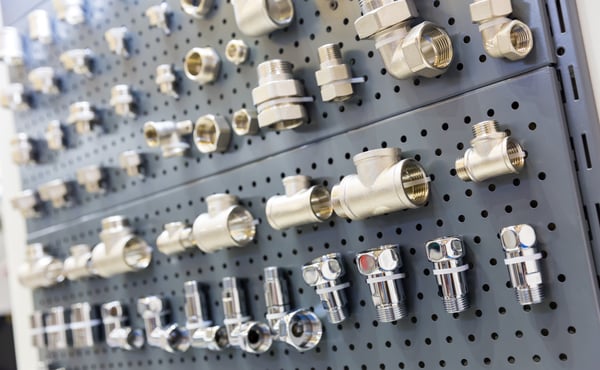

Pipe Fittings: are pieces that connect pipe sections together and help change the direction of piping. They also adapt pipes to different shapes and sizes and help regulate and measure fluid flow.

Types of PVF

PVF varies widely in both material and function. Depending on the application, different types of metals and non-metals are used to ensure successful and safe operating conditions. The material selection, as well as sizing, depends upon parameters such as substance, pressure, temperature and flow rate. Typically, pipe fittings and valves are made of the same material as the pipe.

Pipe:

Pipes come in all types of different shapes, sizes, and material. The type of pipe used in a piping system is determined by the process conditions involving type of substance, temperature, and pressure. The most commonly used types of pipes include:

- Steel: steel pipes are best known for their strength and are commonly used underground to transport water, gas, and sewage throughout cities and towns. These pipes are manufactured using different methods to produce both welded and seamless varieties.

- Galvanized steel: galvanized steel pipes are coated with zinc to help prevent rust and corrosion and can last up to 100 years! Galvanized pipes are typically used in construction, water supply lines, outdoor applications, and underground applications.

- Stainless Steel: stainless steel pipes are used in areas subject to corrosion and areas with strong sanitation needs such as the food/beverage and healthcare industries. Among these types of pipes, stainless steel grade 304 is the most commonly used alloy for its high corrosion and chemical resistance.

- Cast Iron: cast iron pipes are commonly used for water distribution systems. These pipes are heavier than any other pipes and can be found underground as the main pipe for drainage or sewer systems.

- Copper: copper pipes are commonly used for water supply and refrigerant lines because of their ability to resist corrosion and high temperatures. Copper piping comes in two different forms–rigid copper and soft copper. Rigid copper is a popular choice for water lines and cannot be bent, whereas soft copper is ductile and typically used in refrigerant lines. Copper piping is organized by its wall thickness, with the most common types being Type K, Type L, and Type M.

- Type K has the thickest walls and is often found in water distribution systems and the oil industry.

- Type L has a thinner wall section and is the most common variety out of the three, often being found in residential and commercial plumbing systems.

- Type M has the thinnest wall and tends to be found in drain, waste, and vent lines.

- Aluminum: aluminum pipes come in several different alloys making them extremely versatile. Because these pipes have excellent corrosion resistance and workability, they are found in a range of industries including aerospace, automotive, and medical.

- Plastic: plastic pipes are used for a large range of applications and are made out of several different types of material. The most common are ABS, PVC, and PEX.

- ABS pipes are mainly used in industrial applications and commonly used in oil fields and in the chemical industry.

- PVC pipes are strong, chemical-resistant, and are commonly used for drain lines and in residential homes.

- PEX pipes are the newest type of plastic pipe for water distribution in buildings and are known for their flexibility, heat-resistance, and long-term durability.

Valves:

Valves come in an array of different sizes, styles, and pressure rating classes to facilitate the flow and pressure of substances. Different types of valves are used depending upon function and application. Selecting the correct valves is essential to any piping system operation. Here’s a list of some commonly used valves and their application:

- Ball Valves: a one-way valve that is opened and closed by pressure on a ball which fits into a cup-shaped opening.

- Butterfly Valves: isolates or regulates fluid flow.

- Check Valves: a valve that closes to prevent the backward flow of liquid.

- Diaphragm Valves: used to start/stop and control fluid flow.

- Float Valves: a simple mechanical liquid level controller.

- Gate Valves: used to shut off the flow of liquids rather than for flow regulation.

- Globe Valves: a type of valve used for regulating flow in a pipeline.

- Needle Valves: designed to allow precise flow control.

- Plug Valves: a cone or cylinder-shaped valve that uses a rotator inside the valve body to control the flow of fluids.

- Solenoid Valves: used to control the flow or direction of air or liquid in fluid power systems.

- Pressure Relief Valves: a safety valve used to control or limit the pressure in a system.

Pipe Fittings:

The materials used for pipe fittings depend on the type of piping system and operating conditions. Typically, they are made out of the same materials used in the pipes they help join. Some common materials used to make fittings include PVC, PE, ABS, PP, nylon, aluminum, stainless steel, steel, copper, cast iron, and brass. Here’s a list of some commonly used pipe fittings and their application:

- Elbows: for making angle turns in piping and changing the direction of fluid flow.

- Tees & Crosses: for making branch line connections at 90 degrees and changing the flow of fluid.

- Plugs & Caps: for closing off open pipe ends or fittings.

- Couplings: for connecting two pieces of pipe of the same size in a straight line.

- Nipples: small pieces of pipe threaded on both ends used for making close connections.

- Unions: joins the ends of two pipes and makes it easier for dismantling.

- Ferrules: for joining or binding one part of piping to another.

How is PVF Used?

When all put together, the individual components of PVF form what are known as piping systems. Piping systems are networks of pipes, fittings, and valves intended to perform a specific job by carrying substances from one place to another.

Piping systems are a necessary part of living in an industrialized society and help transport everything from the steam in nuclear power plants and oil in refineries to the gasoline used in automobiles and water supplied inside buildings.

Did you find this information interesting? Check out the Boyd Metals Blog page for more info about the metals industry, and don't forget to download our FREE Guide to Pipe Sizes.