"Before anything else, preparation is the key to success."

- Alexander Graham Bell

While no one can predict the future, if history teaches us anything it's that the most successful businesses are the ones prepared to pivot in the face of adversity. In the metal industry, that means being able to constantly rise above a multitude of challenges - economic crashes, price spikes, material shortages, drops in demand, broken supply chains, global pandemics, and the list goes on.

For us here at Boyd Metals, we have been fortunate enough to weather more than just a few storms in our day and come out on the other side. A large part of this has been due to our ability to prepare for and adapt to times of uncertainty.

In fact, we had the privilege of sitting down with Modern Metals' Corinna Petry to discuss some of the ways our company is preparing for the future ahead.

In this article, our vice presidents and general managers provide an inside look into some of the major investments we've made in new processing equipment, market expansion, and employee training.

An excerpt from the story follows:

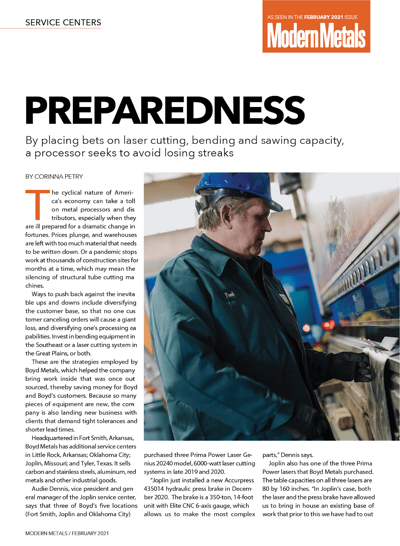

"The cyclical nature of America’s economy can take a toll on metal processors and distributors, especially when they are ill prepared for a dramatic change in fortunes. Prices plunge, and warehouses are left with too much material that needs to be written down. Or a pandemic stops work at thousands of construction sites for months at a time, which may mean the silencing of structural tube cutting machines.

Ways to push back against the inevitable ups and downs include diversifying the customer base, so that no one customer canceling orders will cause a giant loss, and diversifying one’s processing capabilities. Invest in bending equipment in the Southeast or a laser cutting system in the Great Plains, or both.

These are the strategies employed by Boyd Metals, which helped the company bring work inside that was once outsourced, thereby saving money for Boyd and Boyd’s customers. Because so many pieces of equipment are new, the company is also landing new business with clients that demand tight tolerances and shorter lead times."