Press brakes are a vital piece of metal-forming equipment that allows our team to deliver products ready for immediate use on-site. Getting precision bends and right angles according to specs is key to keeping work moving on time and on budget. Some of the most common requests we handle range from complex to simple and include:

- Forming complex shapes: Press brake bending can be used to form complex shapes that would be difficult or impossible to achieve with other metal fabrication methods. This makes it ideal for producing parts with intricate geometry or irregular contours.

- Creating precise bends: Press brake bending allows for the creation of precise bends with a high degree of accuracy. The punch and die can be designed to produce bends with specific angles and radii, making it ideal for producing parts with precise dimensions and tolerances.

- Improving efficiency: Press brake bending can be more efficient than other metal fabrication methods, especially when producing large quantities of parts. It allows for the rapid production of parts with consistent quality and can reduce the overall cost of production.

- Working with a variety of materials: Press brake bending can be used to work with a wide range of materials, including steel, aluminum, brass, and copper. This versatility makes it a popular choice for many metal fabrication applications.

At Boyd Metals, our in-house sheet metal bending services offer a cost-effective, customizable solution for your metal bending tool needs. We offer full 3D programming, bend visualization, and dynamic viewing during the forming process. Our large-format press break delivers impressive ram open heights and stroke lengths to provide flexibility for complex part designs. Dynamic Thickness Compensation (DTC) automatically compensates for variations in material thickness.

With our five locations (Oklahoma City, OK, Tyler, TX, Joplin, MO, Ft. Smith, AR and Little Rock, AR), we serve a five-state area with our three different press brake models:

- Accurpress Accell E brake

- 230-ton Cincinnati Proform brake

- 350-ton Accurpress Accell E brake

Don’t just order from Boyd for the amazing selection and one-stop shopping, but consider our expert processing services (including access to our pro sheet metal bender) as a key benefit to saving you time and money on each project. We want to be a part of your next success.

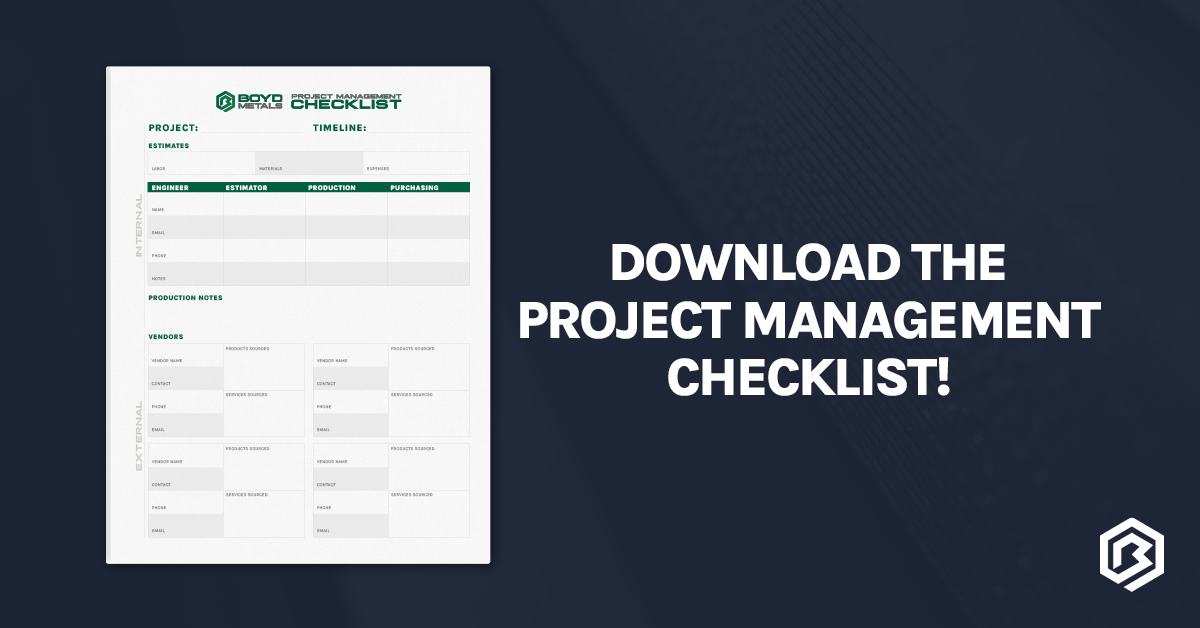

Need a helpful way to stay organized on big projects?

Whether it's ordering our top-of-the-line industrial products, experiencing our unmatched processing capabilities or using one of our FREE resources, we're always here to help. Download our Project Management Checklist for an easy way to stay organized while you're on the job!