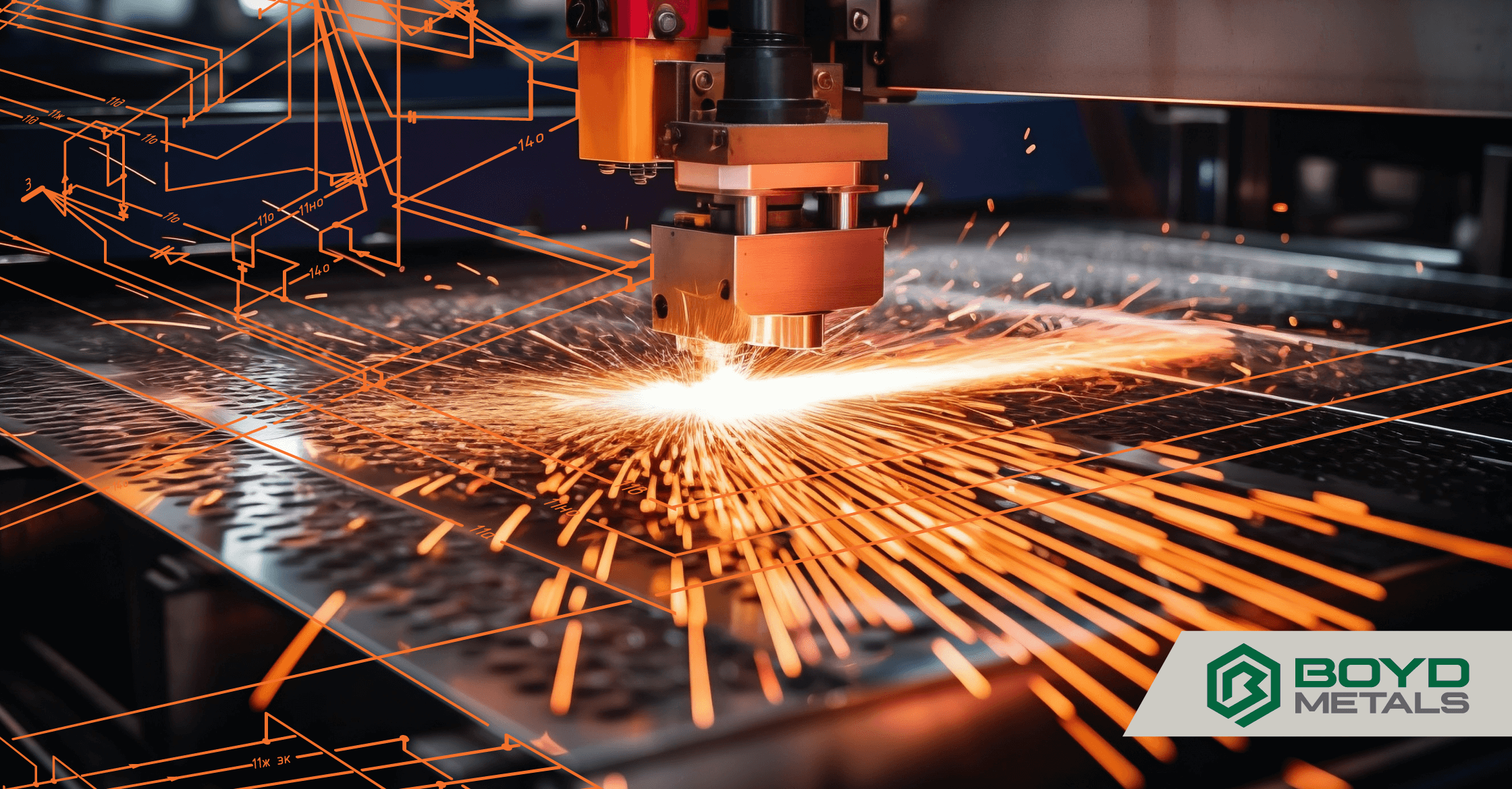

As a project manager, you know that meeting deadlines and maintaining quality standards often comes down to having the right processing partner with the right equipment. Boyd Metals, your reliable metals service center, has invested in state-of-the-art processing equipment across five strategic locations, providing the precise cutting and forming capabilities your projects demand.

Advanced Cutting Technologies for Superior Edge Quality

When it comes to precision and edge quality, each sheet metal cutting method in our arsenal serves a specific purpose:

- Fiber Laser Cutting: Our PRIMA POWER 6K and BYSTRONIC BYCUTSTAR systems deliver exceptional edge quality for materials up to 1" thick, ideal for projects requiring minimal post-processing. These systems maintain tight tolerances while handling sheet metal up to 80" x 160".

- Plasma Cutting: For heavier materials, our ALLTRA plasma systems can handle thicknesses up to 5" with impressive speed. Our latest 400 AMP systems in Oklahoma City feature massive 12' x 62' tables, perfect for large-scale projects requiring both volume and precision.

- Saw Cutting: For structural materials and precise angle cuts, our HYDMECH and HEM saws provide clean, accurate cuts with capabilities up to 30" x 25".

Regional Processing Power When and Where You Need It

Looking for where to buy sheet metal? As a leading metal company, we've strategically equipped our five locations to serve your specific regional needs:

- Fort Smith, AR: Home to our BYSTRONIC BYCUTSTAR 4020 20KW laser and advanced tube processing capabilities, handling sheets up to 6' x 13'

- Oklahoma City, OK: Dual 400 AMP plasma systems with industry-leading table sizes

- Joplin, MO: PRIMA POWER 6K fiber laser and comprehensive forming capabilities

- Little Rock, AR: Complete range of sawing and plasma cutting options

- Tyler, TX: Versatile processing capabilities, including high-capacity brake forming

Material Thickness Capabilities Across Technologies

Understanding which processing method best suits your material thickness is crucial for project efficiency and quality results. For light gauge materials ranging from 14ga to 1/4", our laser cutting systems provide superior edge quality and maintain exceptionally tight tolerances, making them ideal for precision components.

When working with medium-thickness materials from 1/4" to 1", you have the flexibility to choose between our laser and plasma cutting systems, depending on your specific edge quality requirements and project specifications. For heavy plate applications ranging from 1" to 5", our specialized plasma and oxy-fuel systems deliver reliable, efficient processing while maintaining excellent cut quality even at maximum thicknesses.

Project Efficiency Benefits

Choosing the right processing method and location for your project directly impacts your timeline and bottom line:

- Optimal equipment selection reduces secondary operations and handling time. For example, our precision laser cutting can eliminate the need for additional finishing operations, saving both time and labor costs.

- Strategically placed facilities minimize transportation costs and delivery time.

- Regional processing capabilities support faster turnaround times.

- Dedicated project coordination, with direct access to processing updates and status reports, keeps your job moving efficiently through our facility.

Large-Scale Project Solutions

Boyd Metals delivers impressive capabilities across our locations when your projects demand significant processing capacity.

Our Oklahoma City facility leads the way with twin 400 AMP plasma systems featuring expansive 12' x 62' tables, allowing for exceptional throughput on large-scale projects.

In Fort Smith, our 11' x 60' plasma cutting capability handles oversized materials with precision and efficiency. Additionally, across multiple locations, we maintain press brake capacities up to 350 tons x 16', providing the versatility needed for even the most demanding forming requirements. This distributed capability gives you access to large-scale processing power wherever your projects take you.

Want to know exactly which capabilities are available at your nearest Boyd Metals location?

Download our Processing Equipment Line Card for detailed specifications and capabilities across our different locations.

With this guide in hand, you'll have instant access to our complete processing capabilities, helping you plan more efficiently and make confident decisions for your next project.