The creation of steel itself is a complicated process. We can't cover it in-depth here, but let's talk about the basic process that is behind the majority of steel products.

Iron ore is found naturally in the earth and mining for ore provides thousands of jobs throughout the world each year. It is a major industry for many countries. The iron ore is "smelted" under extreme heat inside blast furnaces. The heat is intense enough to liquefy the rocky ore. Components of the ore react differently to the heat - some float above the raw iron and some sink beneath it. The desired product can be collected, leaving the unwanted portions behind.

Raw Iron Ore

Blast Furnace Door

The basic iron ore is already useful for many applications, but it isn't "steel" just yet. In another blast furnace, unwanted elements such as phosphorous, sulfur and excess carbon are removed. After impurities have been removed, it is then fortified with elements such as nickel, chromium, and manganese. One or more of these are added to create a range of steels - each uniquely suited to perform best under specific circumstances.

Pouring molten metal into a form

Combining molten elements in a furnace

The molten ore is typically poured into billets, blooms or slabs. These basic metal shapes can be re-heated and manipulated into the other "long" or "flat" products. In most cases, billets and blooms are used when rolling long products. Because billets are smaller, they are used to roll long products that are smaller as well. When rolling flat products, slabs are used.

"Billets"

"Blooms"

"Slabs"

Semi-finished slabs, blooms or billets all pass through a reheating process. This involves being heated in a furnace that is nearly 2,200 degrees Fahrenheit. The pieces then move along to the roughing stand where they are squeezed into the desired shapes. Large pieces often take several passes through the roughing stand in order to obtain the shape of the finished product.

All rolled steel passes through a cooling phase which is extremely important. The steel's mechanical properties are affected by the speed at which it is cooled.

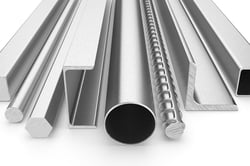

Long Products

Long Product Mills

Long products are made of billets and blooms. They are milled as a long, continuous bar of steel; hence their name. However, they can be made in a range of different sizes and shapes. Long products reach their desired shape due to being passed through a series of stands that mold the steel while also changing its size. Examples of "long products" include beams, joists, and bars in shapes such as hexagons, squares or angles.

Plate Products

Plate Mills

Plates are made by running slabs through a finishing stand. These flat pieces of steel can be up to 15 feet wide and vary in thickness from 1/3 of an inch to two inches. Plate is often used to make tanks, ship hulls and boilers.

Strip or Coil Products

Strip Mills

Steel strip - also often referred to as hot rolled coil - is also produced from slabs. The finishing stands used in strip mills squeeze the steel continuously to make it thinner. It is coiled at the end of the process to make it easier to handle. Among many other things, hot rolled coil can be used to make small tubes.